- Basic Description FANUC Robotics’ OlpcPRO is a state-of-the-art offline robot. N A built-in ASCII editor is also available to edit, load and save TP programs in ASCII. PC software such as FANUC Robotics’ vision software, third-party HMI software. Select JNT on the screen or select COORD (button in the teach pendant) to select the joins mode.

- FANUC offers an easy way to command and configure a robot from a PC using their PC Developer's Kit ( PCDK ).The kit allows a PC to access variables, registers, IO, programs, positions, and alarms on the robot. Most of the help documentation already covers Visual Basic, so I'll explain how to get started with C#.

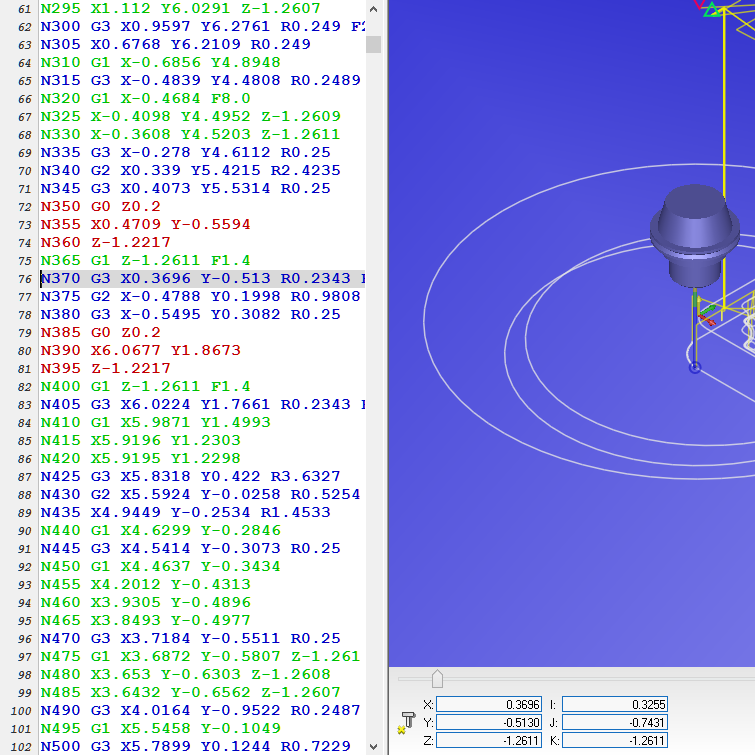

FANUC’s TP programming language and the teach pendant’s built-in editorare great tools. They allow relatively novice programmers to get up andrunning very quickly. Teach a couple points, throw in a couple labelsand IF statements, and you’re off to the races. However, anyone who’stried to do anything a bit more complex quickly realizes how cumbersomeprogramming on the teach pendant is. Navigating through multiple levelsof menus to find the PAYLOAD instruction or creating an extensivemixed-logic conditional is really painful. At this point manyprogrammers switch to programming .LS files by hand.

Here’s the smallest program you can load onto a robot:

FANUC Robot Software Options. With more than 250 software functions for enhanced intelligence, motion, safety and productivity, we give you the power to make your robots see, feel, learn and keep you safe. FANUC robot software products include dedicated functions, simple to use interfaces and exclusive features to simplify and standardize robot. Fanuc tp editor software download I have some questions to generate a robot program and to download to a proper controller: What kind of. What is an.LS file? The.LS file extension is the same as a text file.

However, it might be good practice to start with a template thatincludes all available sections:

The /PROG section simply accepts the name of your program (letters,numbers and underscores only, and it must start with a letter) followedby an optional sub-type (e.g. Macro, Cond, etc.).

The /ATTR section stores the rest of the program header information:things like the creation date, comment, group mask, etc. If you choosenot to include any of this, the robot assumes a sensible set ofdefaults.

I’m not sure what /MN stands for (motion?), but this is where yourprogram goes. You must start each line with a : and end it with a ;.You can optionally include a line number before the colon, but I thinkincluding line numbers in your source code is a tragedy.

At this point there’s no good way of populating the /POS section ofyour program. I generally upload my program to the robot, teach thepoint, then use the robot web page to view the program source andcopy/paste the position data after positions are taught. Maybe I’llwrite something better someday.

Getting the Files to Your Robot

Unfortunately FANUC decided to squeeze an additional $500 out ofanyone who needs to do any real programming. The robot will nottranslate your ASCII *.LS files into binary .TP files unless youpurchase the ASCII Upload option.

If you’re lucky enough to have a ROBOGUIDE license, you can side-stepthe ASCII Upload option by having your virtual robot translate them foryou.

Here’s a simple Windows Batch file and FTP script that will upload all.LS files located in ./src to the virtual robot on 127.0.0.2and then download the .TP files into ./bin:

Note: keep an eye on your virtual robot’s error log or the FTP outputto see if any files failed to translate. Also make sure your thecurrently selected program on your virtual does not to be translated.(Abort all then select another program.)

You might write another batch file to then upload files to your realrobot at 192.168.1.101:

Note: Again, the robot won’t load a file if that file is currentlyselected on the teach pendant. (Abort all, select another program)

“I Wish I Had Used TP+”

That’s what I said to myself last week while trying to find a rare bughidden within 15000 lines of TP code. The bug ended up being a simpletypo… something like this:

Can you spot the issue? Here’s how it looks after translating andloading the file onto the controller:

I meant to use R[2:numreg two] in both conditionals, but Iaccidentally changed the 2 to a 3 while hastily changing the otherexpressions. The translator ignores the comment completely, so you haveno idea your code doesn’t work until you test it.

This can be particularly catastrophic when using positions and positionregisters. Tell the robot to move to P[10:position one] when you meantP[1:position one] could be pretty bad. Gotta be careful whenprogramming by hand.

TP+ to the Rescue

Here’s how this program might look if written with TP+:

Of course you can still make typos, but I think it’s a lot harder tomis-type names than numbers. The translator will catch it if you typenmrg_one instead of numreg_one.

Fanuc Tp Editor Software Reviews

Interested?

Fanuc Tp Editor Software Windows 10

I introduced TP+ back in January.There’s a demo where you can try it out.

I used TP+ exclusively on my most recent machine tending project, and itwas really refreshing. A single environment file holds all variables fornumeric registers, position registers, I/O, etc. Namespaces allow me toorganize data and I/O into logical groups independent of the robot datanumbering.

Let’s say you have to move DI[1] to DI[56] for some reason, and this inputis used in 100 programs. Simply update the variable definition in theenvironment file, re-translate and all the programs are instantlyup-to-date.

I’ll release a standalone version of TP+ eventually. Let me know ifyou’re interested and I might get it done sooner rather than later.

FANUC ROBOGUIDE Simulation Software the industry's most robust robot simulation products ROBOGUIDE is the leading of offline programming product on the market for FANUC robots. The ROBOGUIDE family of process focused software packages allows users to create, program and simulate a robotic workcell in 3-D without the physical need and expense of a prototype workcell setup. With virtual robots and workcell models, of offline program- ming with ROBOGUIDE reduces risk by enabling visualization of single and multi-robot workcell layouts before actual installation. Contact us today - we'd be happy to speak with you regarding FANUC ROBOGUIDE Simulation Software.

Download Tp Editor Software Download - best software for Windows. TPEditor: TPEditor is a programming application designed for Delta text panels operating on Windows. You cannot covert the *.pc files they are FANUC source code, they have been coverted from ASCII using ktrans to machine language and cannot be converted back to ASCII. FANUC's TP programming environment is great for creating simple programs. Real intelligence to your robot, you'll quickly find the editor to be cumbersome.

ROBOGUIDE - PalletPRO and PalletTool PalletPRO simulation software can be used to completely build, debug and test a palletizing application offline. PalletPRO allows users to create a workcell layout, infeed and pallet stations, slip sheet and pallet dispensers. Company of heroes 2 reviews. Hundreds of unit load pallet configurations can be created and visualized in 3-D using PalletPRO’s built-in library of industry standard patterns. The data created in PalletPRO can be downloaded to a real robot controller containing PalletTool® software.

To find the latest driver, including Windows 10 drivers, choose from our list of most popular Logitech Camera downloads or search our driver archive for the driver that fits your specific Camera model and your PC’s operating system. Welcome to the Logitech Community Webcam Forum hpel! Hpel sez - I apologize for posting after 6 months but I'm having the same problem with the same model, only the link you provided no longer works. Logitech 8k89 ite camera driver windows 7. How to install my 8k89 i t e camera in my pc i have lost my install cd and now i want to install the same camera in another pc. Thanks This thread is locked.

Fanuc Tp Editor Software Update

FANUC Picture offers an easy way to create customised operator and HMI screens for complex processes and provides all the functions and features of modern HMI software tools. It supports objects, animations, data and multi language, and features a macro language to run routines to perform tasks. Screens are compiled and stored in the CNC Flash-ROM (FROM) memory and rendered directly by the CNC without requiring a Windows® operating system or runtime. Picture reduces operator errors, simplifies operator work, improves productivity and makes machine and process control easier.